Ultra-Precision Optics: The Pinnacle of Optical Accuracy and Innovation

Ultra-precision optics represents a cutting-edge field within optical technology, characterized by the development and application of optical components and systems with exceptional accuracy and performance. This comprehensive guide explores the essence of ultra-precision optics, its key applications, advancements, and future trends.

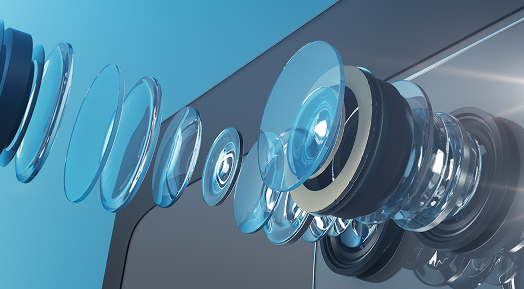

1. What is Ultra-Precision Optics?

Ultra-precision optics refers to optical systems and components designed with an extraordinary degree of precision. This field involves creating optical elements that achieve extremely high levels of accuracy in their measurements, manufacturing, and performance, often down to the nanometer scale.

1.1 Characteristics of Ultra-Precision Optics

- Extreme Accuracy: Ultra-precision optics are engineered to meet stringent tolerances and specifications, ensuring that optical systems perform with minimal deviations.

- High-Resolution Performance: These optics are designed to provide high-resolution imaging and measurement, critical for applications that require detailed and precise information.

- Advanced Manufacturing Techniques: The production of ultra-precision optics involves sophisticated techniques and technologies to achieve the necessary precision.

1.2 Applications of Ultra-Precision Optics

Ultra-precision optics are utilized in various fields where high accuracy and performance are essential.

- Scientific Research: In research environments, ultra-precision optics are crucial for experiments requiring precise measurements and observations, such ultra-precision optics as in quantum optics and particle physics.

- Medical Devices: Precision is critical in medical imaging and diagnostic equipment, where ultra-precision optics enhance clarity and accuracy in tools like endoscopes and laser surgery systems.

- Astronomy and Space Exploration: High-resolution optics are used in telescopes and space probes to observe distant celestial objects with great detail and accuracy.

- Manufacturing and Metrology: Ultra-precision optics are employed in manufacturing processes and metrology for quality control and the precise measurement of components and materials.

2. Techniques and Technologies in Ultra-Precision Optics

Several advanced techniques and technologies are employed to achieve the high levels of precision required in this field.

2.1 Precision Fabrication

- Optical Polishing: Ultra-precision optics often require advanced polishing techniques to achieve the desired surface quality and shape, minimizing surface errors and aberrations.

- Diamond Turning: This method uses a diamond-tipped tool to machine optical surfaces with high precision, commonly used for creating complex optical elements.

2.2 Metrology and Testing

- Interferometry: A key technique in ultra-precision optics, interferometry measures optical wavefronts and surface profiles with extreme accuracy, detecting even the smallest deviations.

- Fizeau Interferometry: Used for testing optical surfaces, Fizeau interferometers measure the quality of optical components by comparing them to a reference surface.

Read also: Emerging and Future Use Cases of Emotion Recognition Technologies

2.3 Materials and Coatings

- Advanced Optical Materials: The use of high-quality optical materials, such as low-expansion glass and specialty crystals, ensures minimal distortion and high performance.

- Specialized Coatings: Optical coatings, such as anti-reflective and reflective coatings, are applied with precision to enhance optical performance and reduce unwanted effects.

3. Challenges in Ultra-Precision Optics

Achieving ultra-precision in optics involves addressing several challenges and considerations.

3.1 Manufacturing Complexity

The complexity of manufacturing ultra-precision optics requires advanced equipment and highly controlled environments to maintain the desired precision. Ensuring consistency across production batches is crucial.

3.2 Cost and Accessibility

The high level of precision and the advanced technologies involved can result in significant costs. Balancing cost with performance while ensuring accessibility for various applications is a key consideration.

3.3 Environmental Factors

Environmental factors such as temperature fluctuations and vibrations can affect optical precision. Maintaining stable conditions and implementing compensatory measures are essential to preserve performance.

4. Innovations and Future Directions

The field of ultra-precision optics is continually evolving, with ongoing advancements driving new possibilities and applications.

4.1 Adaptive Optics

- Real-Time Adjustments: Adaptive optics systems can make real-time adjustments to optical components, compensating for distortions and improving precision in dynamic environments.

4.2 Nanotechnology

- Nanofabrication: Advances in nanotechnology enable the fabrication of optical components with nanometer-scale precision, expanding the possibilities for ultra-precision optics.

4.3 Integration with Digital Technologies

- Smart Optics: Integration with digital technologies, such as AI and machine learning, allows for smarter optical systems that can adapt to varying conditions and optimize performance.

4.4 Quantum Optics

- Quantum-Level Precision: The field of quantum optics explores the use of ultra-precision optics in quantum computing and communication, pushing the boundaries of measurement and accuracy.

5. Conclusion

Ultra-precision optics stands at the forefront of optical technology, offering unparalleled accuracy and performance across various applications. By leveraging advanced techniques, technologies, and innovations, this field continues to drive advancements in scientific research, medical devices, astronomy, and manufacturing. Understanding the principles, challenges, and future directions of ultra-precision optics allows for the exploration of new possibilities and the achievement of exceptional performance in optical systems. As technology evolves, ultra-precision optics will remain a critical component in advancing our understanding and capabilities in the optical domain.