Harnessing AI and Computer Vision for Predictive Maintenance

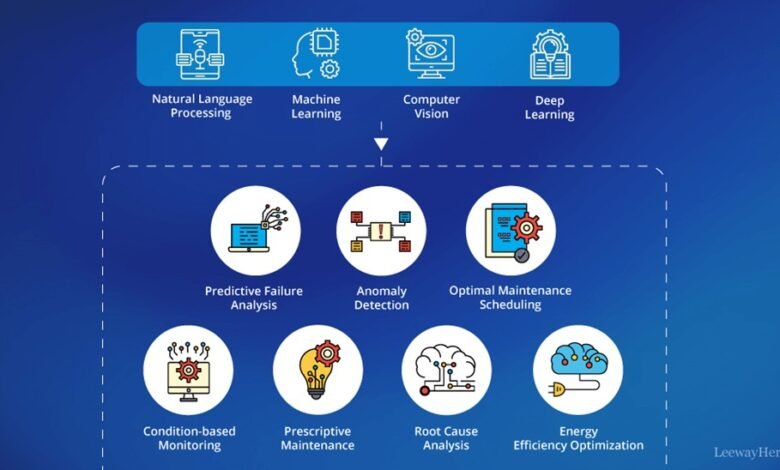

Predictive maintenance is a game-changer for industries relying on complex machinery and equipment. By leveraging advanced technologies such as Artificial Intelligence (AI) and computer vision, businesses can anticipate equipment failures before they occur, minimizing downtime and extending the lifespan of their assets.

The Role of AI in Predictive Maintenance

AI in predictive maintenance involves using machine learning algorithms and data analytics to forecast equipment failures. AI models analyze historical data, operational conditions, and sensor inputs to predict when a machine is likely to fail. This proactive approach allows organizations to perform maintenance only when necessary, rather than adhering to a fixed schedule.

Key benefits of AI in predictive maintenance include:

- Reduced Downtime: By predicting failures before they happen, AI helps prevent unexpected equipment breakdowns, thereby reducing operational downtime.

- Cost Savings: Predictive maintenance reduces the need for costly emergency repairs and helps optimize maintenance schedules, leading to cost savings.

- Increased Equipment Lifespan: Timely maintenance extends the lifespan of machinery by addressing issues before they cause significant damage.

Integrating Computer Vision with Predictive Maintenance

Computer vision plays a crucial role in enhancing predictive maintenance strategies. Computer vision development enables machines to interpret and analyze visual data from cameras and sensors. By incorporating computer vision, businesses can monitor equipment condition in real-time and detect anomalies that might indicate potential failures.

Here’s how computer vision complements predictive maintenance:

- Real-Time Monitoring: Computer vision systems can continuously scan equipment for signs of wear, corrosion, or other issues, providing real-time insights into equipment health.

- Anomaly Detection: Advanced algorithms can identify unusual patterns or defects that might be missed by human inspectors, allowing for earlier intervention.

- Visual Data Integration: Combining visual data with AI predictions enhances the accuracy of failure forecasts, as the system can analyze both numerical data and visual evidence.

Case Studies and Applications

Numerous industries benefit from the integration of AI and computer vision in predictive maintenance:

- Manufacturing: In manufacturing plants, AI and computer vision are used to monitor assembly lines and machinery, ensuring early detection of issues that could lead to production stoppages.

- Energy Sector: Power plants and energy facilities use these technologies to monitor turbines, pumps, and other critical equipment, optimizing maintenance schedules and reducing operational costs.

- Transportation: In the transportation industry, predictive maintenance systems equipped with computer vision help monitor the condition of vehicles and infrastructure, improving safety and reducing maintenance expenses.

Conclusion

Combining AI with computer vision offers powerful solutions for predictive maintenance, transforming how businesses manage their equipment and operations. By utilizing AI in predictive maintenance and integrating it with computer vision development, organizations can achieve greater efficiency, lower costs, and enhanced reliability. Embracing these technologies not only ensures optimal performance but also drives innovation in maintenance strategies.